Cordless Vacuum Cleaner Manufacturers

-

DY-807A Handheld Multifunctional All-in-One Wireless Ultra Light Vacuum Cleaner

DY-807A Handheld Multifunctional All-in-One Wireless Ultra Light Vacuum Cleaner

-

DY-809A Vacuum Cleaner with Ultra Light Wireless Upright Efficient Cleaning

DY-809A Vacuum Cleaner with Ultra Light Wireless Upright Efficient Cleaning

Suitable for portable light-duty cleaning (laptop/keyboard dust, travel use) with models like DY-102, DY-807, DY-103, this series is produced with ultra-light materials (net weight 0.55kg-2.3kg), miniaturized components (100-150ml dust cups) and efficient assembly; it offers travel-friendly support (battery carry-on advice) and rapid parts delivery, and has advantages of extreme lightweight, BLDC motor benefits (e.g., DY-807 with 10-28kPa suction and ≤76dB noise) and optimized battery life (12-25mins working time).

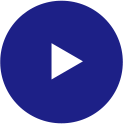

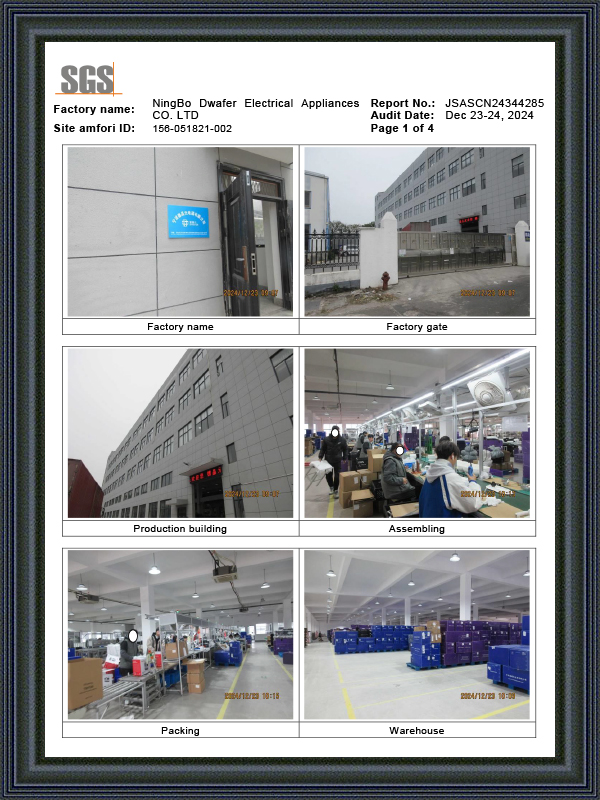

As China Cordless Vacuum Cleaner Suppliers and OEM/ODM Cordless Vacuum Cleaner Manufacturers, Founded in 2019, our company is a high-tech enterprise specializing in the R&D and production of cleaning appliances. Our main products include portable carpet and upholstery cleaners, portable vacuum cleaners, and cordless robotic pool cleaners.

As a nationally recognized high-tech enterprise, we operate a 18,000-square-meter digital production facility and an intelligent benchmark factory, complemented by a 500-square-meter urban office space. Our carpet cleaner production capacity reaches 3,000 units daily. Leveraging years of technical expertise in power line communication, we have established specialized R&D teams in Ningbo and Suzhou, holding over 40 patents.

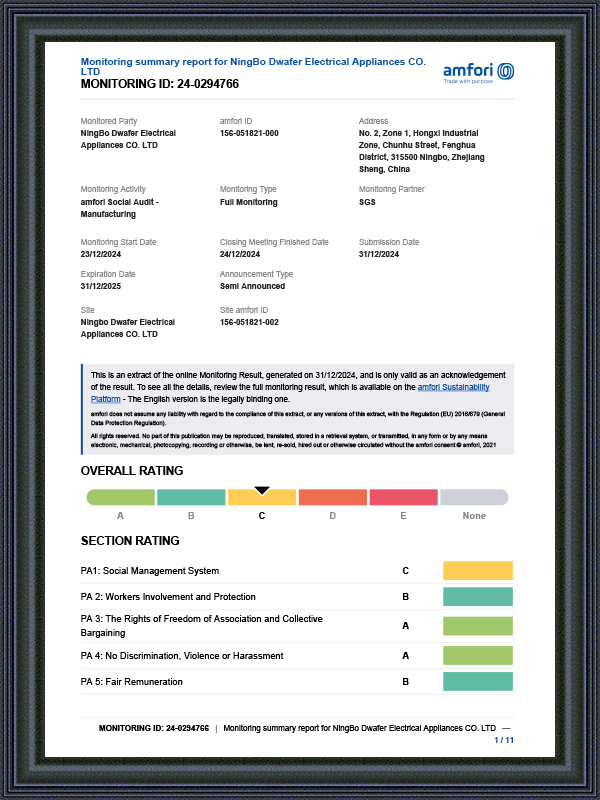

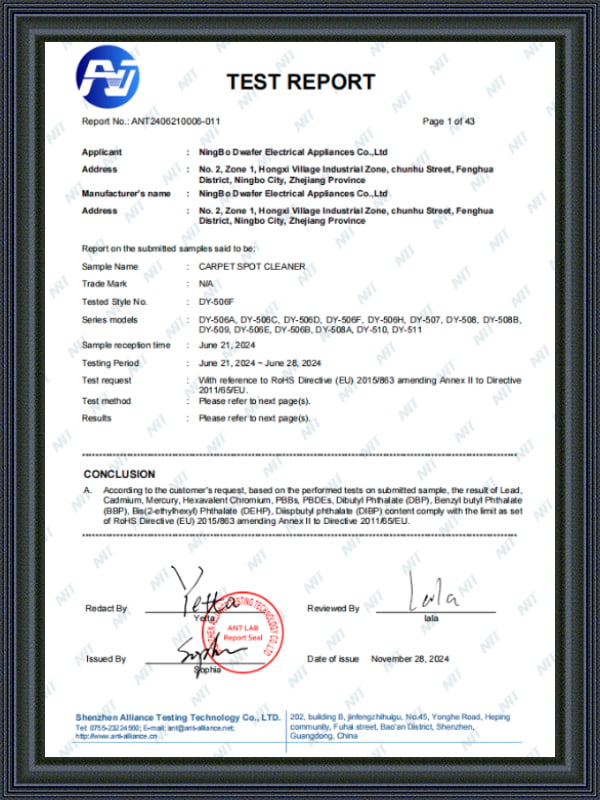

The company holds ISO9001:2008 Quality Management System certification and BSCI compliance. Most products carry authoritative certifications including CCC, CB, CE, GS, ETL, ROHS, and REACH.

-

0

Founded In

-

0+

Company Staff

-

0+m²

Area Covered

-

2026-02-25

Industry News

2026-02-25

Industry News

-

2026-02-18

Industry News

2026-02-18

Industry News

-

2026-02-11

Industry News

2026-02-11

Industry News

Is the battery life of the cordless vacuum cleaner stable?

Factors That Influence the Stability of Battery Life

The stability of a cordless vacuum cleaner’s battery life depends on several technical factors, including battery capacity, internal cell structure, power management systems, and the type of cleaning tasks performed. Lithium-ion batteries, which are commonly used in cordless vacuums, usually provide steady discharge performance due to their chemistry and energy density. However, the consistency of runtime may vary depending on the suction level selected, debris type, and how frequently the vacuum is used. As a battery approaches the end of its life cycle, its stability may gradually decline, resulting in shorter operating times. Understanding these factors helps users form realistic expectations regarding long-term stability.

The Role of Power Modes in Runtime Stability

Cordless vacuum cleaners often include multiple power modes, such as low, medium, and high suction. These modes significantly influence how stable the battery performance feels during use. Low or eco modes typically maintain a consistent runtime, allowing users to clean for extended periods without interruption. High-power modes consume more energy and may cause the battery to drain faster, reducing runtime stability. This does not indicate a malfunction but is a normal characteristic of higher suction settings. Choosing the appropriate mode for a specific task helps maintain predictable battery behavior and minimizes unexpected shutdowns.

| Power Mode | Energy Consumption | Runtime Stability |

|---|---|---|

| Eco/Low Mode | Low | Highly stable for extended cleaning |

| Medium Mode | Moderate | Stable for mixed tasks |

| High/Max Mode | High | Shorter and less stable due to rapid power draw |

Impact of Dustbin Load and Filter Condition on Battery Stability

A frequently overlooked factor affecting battery stability is the condition of the vacuum’s filters and dustbin. When the filter becomes clogged with fine dust, the motor must work harder to maintain suction, leading to increased power consumption and reduced runtime stability. A full dustbin can restrict airflow, causing similar effects. Routine maintenance, including emptying the dustbin and washing or replacing filters, allows the vacuum to operate efficiently and prevents unnecessary strain on the battery. These maintenance practices support stable battery performance during both short and extended cleaning sessions.

Environmental Conditions and Their Influence

Temperature plays an important role in determining how consistently a cordless vacuum’s battery performs. Cold environments can temporarily reduce a lithium-ion battery’s ability to deliver energy, leading to shortened runtime. Extremely hot environments may also affect battery efficiency and charging performance. Users who operate their vacuum cleaners in garages, workshops, or outdoor areas may notice fluctuations in battery stability based on seasonal changes. Keeping the device stored in moderate temperatures and charging it indoors can help maintain consistent performance.

Charging Habits and Long-Term Battery Performance

Charging habits influence how stable the battery remains over its lifetime. Lithium-ion batteries generally perform best when charged regularly and not allowed to deplete completely. Overcharging is typically prevented by built-in protection circuits, but storing a fully charged battery for long periods may still affect its aging process. Users who clean frequently and charge the vacuum after each use often experience more stable battery performance than those who let the battery drain fully before reconnecting it. Following the manufacturer’s charging guidelines helps preserve the battery’s consistency and supports reliable long-term operation.

| Charging Habit | Effect on Battery Stability |

|---|---|

| Frequent partial charging | Maintains stable everyday performance |

| Fully draining before charging | May reduce long-term stability |

| Storing battery fully charged for long periods | May accelerate capacity decline |

Motor and Power Management Technologies

Modern cordless vacuum cleaners incorporate electronic control systems that regulate power distribution based on motor load, suction mode, and remaining battery capacity. These technologies help stabilize the battery’s output, especially during routine cleaning tasks. Brushless motors, which are common in many newer models, offer consistent power delivery and help maximize battery efficiency. By reducing friction and heat generation inside the motor, these systems minimize unnecessary power consumption and contribute to predictable runtime behavior.

Real-World Expectations for Battery Stability

In practical terms, users can expect stable runtime performance as long as the vacuum is well-maintained and used under typical household conditions. Changes in suction mode, heavy debris pickup, clogged filters, and temperature fluctuations may cause variations, but these influences are normal and do not indicate poor performance or defects. By selecting appropriate cleaning settings, keeping the vacuum maintained, and using proper charging habits, users can ensure that their cordless vacuum cleaner maintains steady battery life over an extended period.

Is the anti-tangle nozzle design of the cordless vacuum cleaner reliable?

Understanding the Reliability of Anti-Tangle Nozzle Designs

The anti-tangle nozzle design used in cordless vacuum cleaners is intended to reduce hair wrapping and fiber accumulation during operation. Its reliability depends on factors such as structural layout, airflow direction, brush composition, and motor coordination. Many users expect this feature to limit cleaning interruptions, especially in households with long-haired individuals or pets. Evaluating the reliability of such designs requires understanding how the mechanism works and identifying the conditions under which it performs consistently. By examining airflow distribution, bristle spacing, and the separation capability within the nozzle, users can make informed decisions and address potential issues that appear during long-term use.

How Anti-Tangle Mechanisms Function

An anti-tangle nozzle relies on a combination of rotating brushes, comb-shaped separators, and directed airflow to minimize the chance of long strands becoming wrapped around the brush roll. Instead of relying on force alone, these designs attempt to lift and straighten hair while channeling it toward the dust bin. The comb teeth or guiding fins positioned at specific angles help remove hair from the brush as it spins, reducing buildup. When the airflow is stable and the internal path is unobstructed, the mechanism performs more consistently. However, any internal blockage, weakened suction, or misalignment of parts may affect efficiency, making regular inspection important for maintaining proper operation.

Common Factors Affecting Reliability

Several environmental and user-related factors influence the reliability of anti-tangle designs. Hair length, texture, and moisture content can alter how the nozzle interacts with debris. Pet fur behaves differently from human hair, and synthetic fibers from carpets may require higher lift force to prevent wrapping. Additionally, brush rotation speed affects how well the mechanism separates strands, meaning a slowing motor or low battery may reduce the nozzle’s capability. Flooring type also plays a role; thick carpets can create resistance that stresses the brush roll, while hard surfaces allow smoother rotation. Understanding these variables helps users manage expectations and choose models suited to their cleaning conditions.

Material Selection and Structural Design

Material durability influences long-term reliability. Nozzle components such as fins, combs, and brush bases are often made from engineered plastics designed to resist deformation. Flexible bristles help guide hair without trapping it, while more rigid components provide stability. If the material loses shape due to long exposure to heat or mechanical stress, its separating performance may decline. Brush roll diameter and fin spacing must also be compatible with the type of debris commonly encountered. A balanced structure supports stable rotation and keeps hair from migrating into the motor compartment. When manufacturers test these features, their findings often determine the overall reliability rating.

Comparison of Design Characteristics

The following table summarizes common anti-tangle design features and their impact on reliability:

| Design Feature | Function | Influence on Reliability |

|---|---|---|

| Comb-shaped separators | Disentangle hair during brush rotation | Higher consistency when spacing matches debris type |

| Tapered brush roll | Move hair toward suction path | Reduces wrapping when airflow is steady |

| Soft and hard bristle combination | Balance debris pickup with hair control | Supports reliable operation on mixed flooring |

| Guiding fins | Align strands for easier removal | Improves reliability when fins maintain shape |

Maintenance Practices to Improve Performance

Even with an anti-tangle design, proper maintenance is essential for consistent performance. Users should periodically check the brush roll for hidden strands that may accumulate gradually. Cleaning the internal airflow channels prevents suction reduction, which is necessary for hair transport. Inspecting the comb separators ensures they remain correctly aligned, as small shifts may hamper their ability to remove hair from the rotating brush. Battery care is also relevant because reduced power leads to slower brush rotation, making hair separation less effective. Developing a routine cleaning schedule can extend the life of the nozzle and maintain its reliability during demanding cleaning tasks.

Suitability for Different Cleaning Scenarios

The reliability of anti-tangle nozzles varies depending on usage scenarios. For households with pets or individuals with long hair, such designs can reduce cleaning interruptions when maintained correctly. In high-traffic spaces or on textured carpets, the mechanism may need more frequent cleaning to maintain operation. For short sessions or general daily cleaning, anti-tangle nozzles typically offer stable performance, provided airflow and brush speed remain within intended parameters. Users who understand their cleaning environment can select nozzle designs that align with their needs, improving overall efficiency.

Practical User Recommendations

To maximize reliability, users may benefit from several practical steps. Choosing a vacuum cleaner with replaceable or easily removable brush rolls simplifies maintenance. Ensuring the motor and battery operate within recommended levels helps maintain brush rotation speed. Checking that the nozzle opening remains unobstructed supports consistent airflow. Users should match their model to the type of debris they encounter most frequently, as design compatibility plays a significant role in long-term stability. Implementing these recommendations can help achieve dependable performance while reducing time spent on maintenance.

русский

русский Français

Français Español

Español Português

Português Deutsch

Deutsch عربى

عربى

+86-13736068086

+86-13736068086  No. 2, Zone 1, Hongxi Industrial Park, Chunhu Subdistrict, Fenghua District, Ningbo City, Zhejiang Province, China.

No. 2, Zone 1, Hongxi Industrial Park, Chunhu Subdistrict, Fenghua District, Ningbo City, Zhejiang Province, China.